Information On Engine Oils & Quantities, Spark Plugs, Fuel Systems, Electrical Components, Valve Clearances & More.

2-STROKE ENGINE MACHINES:

FUEL REQUIREMENTS:

- Super Unleaded – minimum 97 octane.

PREMIX / 2-STROKE ENGINE OIL & RATIOS:

- Synthetic Racing / Competition designated premix For carburettor 2T models and a designated (generally ‘lower viscosity’) ‘Injector’ type Racing / Competition oil For Fi 2T Models with a separate oil tank and pump. Please refer to your user manual for exact specification on later model-year machines and Fi variant specifics.

PREMIX RATIOS:

- 80cc / 85cc / 100cc / 125cc / 144cc = 33:1 (This equates to 600ml per 20 litres of fuel). TM UK Recommend 40:1 (This equates to 500ml per 20 litres of fuel)

- 250cc / 300cc = 33:1 (This equates to 600ml per 20 litres of fuel)

SPARK PLUG DESIGNATIONS :

- NGK BR9 EG – 85cc. ->2012 / 100cc. ->2012 / 125cc. -> 2024 / 144cc. ->2025. Electrode Gap: 0.7mm

- NGK CR9 EIX – 125cc FI ES/125cc Carb ES. 2025->. Electrode Gap: 0.7mm

- NGK BR9 ECMIX – 85cc / 100cc. 2013->. Electrode Gap: 0.7mm

- NGK BR8 EG – 250cc / 300cc. ->2018. Electrode Gap: 0.7mm

- NGK BKR8 EIX – 250cc/300cc. 2019->. Electrode Gap: 0.7mm

NOTE: it is advised, in light of some issues over the past years by numerous motorcycle manufacturers and variants of their machines, fitted with the NGK BR9 EG type spark plug, having suffered accounts of ‘tip / electrode’ failure thus leading to engine damage, that 125cc and 144cc machines using the NGK BR9 EG have their spark plug designation updated to an NGK R7376-9 plug (NGK stock code 7763) that features a differing electrode set-up. It is advised to fit this plug after the running in process has been completed.

GEARBOX OIL 2-STROKE:

- Racing / Competition Gearbox oil designed specifically for application with a ‘wet clutch’.

GEARBOX OIL QUANTITY REQUIREMENTS:

80cc / 85cc / 100cc / 125cc / 144cc :-

- 550ml in all engines up to model year 2005.

- 600ml in all engines 2006 onward, or, as advised in the user manual.

250cc / 300cc:-

- 700 ml. All models upto 2018, or, as advised in the user manual.

- 650ml. All models 2019 onward

CARBURETION:

Keihin PWK / PWM carburetors. Depending on operating circumstances (track conditions / temperature / elevation) changes can be made to your TM Racing 2-Stroke powered machines caburetion to give optimum performance, these alterations are made by changing the sizes / settings of your main jet, pilot jet, needle clip position and your fuel/air mixture screw. Changes to the carburetion are only advised if the operator has great understanding and specialist knowledge of the effects that each and any change will have upon the fuelling and running parameters of the engine. Engine damage / failure can easily be achieved by using the incorrect fuelling parameters for the conditions and running the engine excessively ‘lean’ on fuel. Please refer to your TM Moto dealer for more information regarding ‘jetting’ your TM Moto machine before proceeding with altering any of these settings, your TM Moto dealer can explain to you the benefits of correct jetting and how to ‘read’ what your engine and spark plug colour is telling you to do.

WARNING: Whilst correct jetting will allow your TM Moto engine to perform at its best in the conditions required, do not attempt to alter these settings with little knowledge or understanding of how these changes affect the behaviour of your engine and the consequences that these changes can lead to if improperly adjusted. Making an error in carburetion settings will cause severe damage to your engine, If unsure contact your TM Moto dealer or TM UK.

NOTE: on 2-Stroke Enduro machines which normally operate with a ‘tick-over’ it may ensure cleaner running of you TM Moto machine if you decrease the pilot jet size to compensate for the increase in fuel/air at low rpm’s. The ‘tick-over’ screw on the Keihin PWK/PWM carburetors is effectively just a device to lift the ‘slide’, therefore the ‘throttle’ is being held open by the tick-over adjuster screw, essentially you are running on part throttle even when you have the throttle closed, this can lead to the symptoms of ‘rich’ running at low rpm’s and can cause hesitancy (bog) from the engine, decreasing the pilot jet size from 42 down to 40 or 38 will counteract this effect and the bike will run correctly. Remember always keep the the carburettor clean and drain after washing to ensure no moisture is trapped inside, moisture can lead to bad running and corrosion of the internal components.

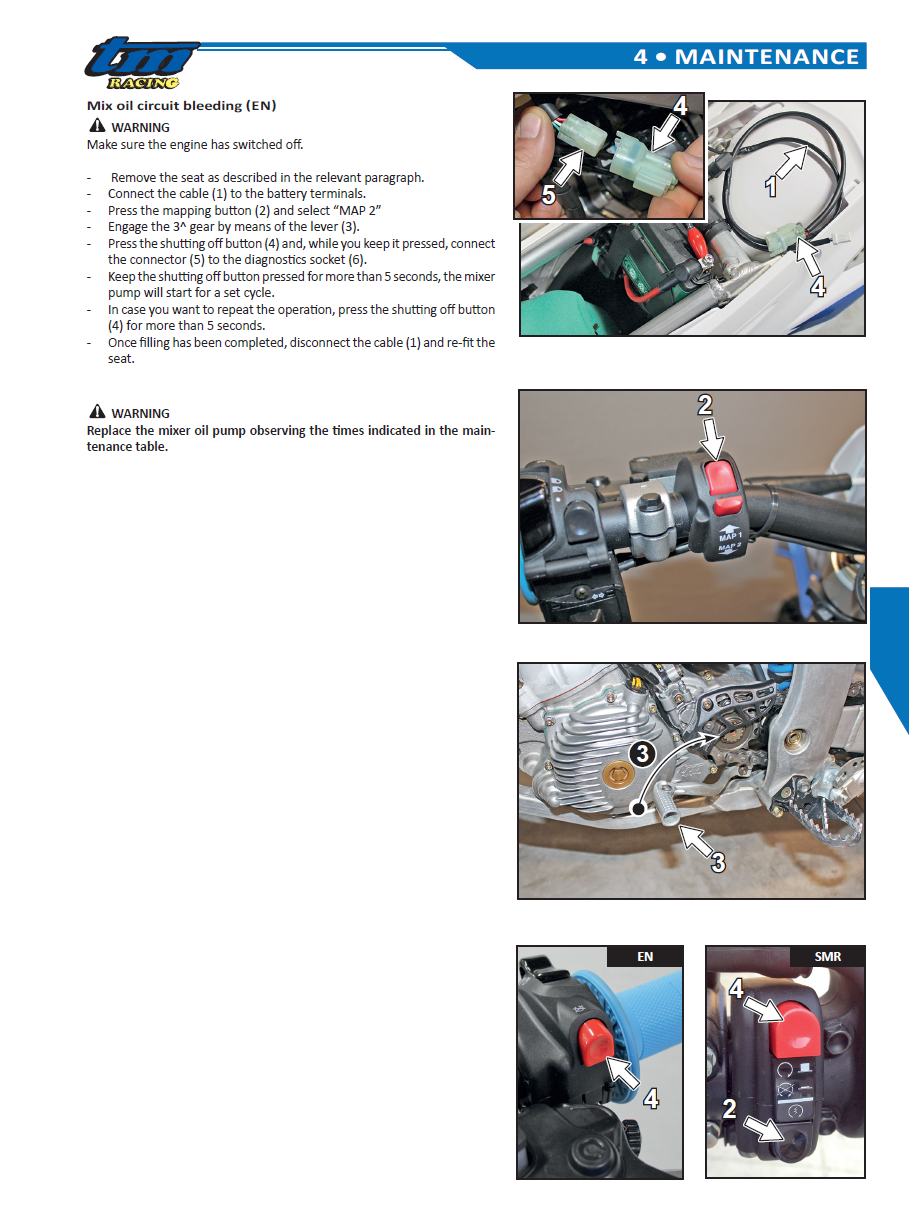

2T Fi (2-Stroke Fuel Injected with separate ‘premix’ oil tank) machines: Oil Circuit Filling and ‘Priming’ of the Pump System with the correct connection cables.

WARNING: You must ensure that the oil injection tank (on versions fitted with) 2T Fi machines is filled and the oil system is ‘primed’ as per the user manual – ‘2 Stroke Oil Circuit Filling’. Priming of the system must be completed after any and all maintenance work that would result in the system losing its ‘pressure’. Failure to adhere to this warning could lead to engine damage. To prime the oil pump and perform simple diagnostic tests you will need the diagnostics port connection cable – Part No 68192. For ECU interfacing via a laptop computer device and the TM Moto software program (once installed) you will require the interface USB cable and diagnostic port connection cable kit – Part No’ F03876.

The section from the user manual relating to the oil circuit filling system ‘priming’ procedure for >2024 125cc/144cc models and 250cc/300cc can be found at the bottom of this page.

2025> Models using the eM103 ECU (Firmware 1.06) – for example the new 2025 125cc E-Start engine models – are primed using the following method:

Engine off:

Engage 2nd gear

Open the throttle fully and keep it in this position (not needed on carburetor models)

Power the electrical system from the diagnosis socket and wait at least 6 seconds.

The purging procedure will begin. (duration approximately 15 seconds)

Check that there are no more air bubbles in the circuit, otherwise repeat the procedure.

At the end of the procedure, return the vehicle to its original condition.

Please note, it is important that the battery is well charged (at least 13V) with the power cables as short as possible, under penalty of failure to start the purge/calibration procedures.

BATTERY REQUIREMENTS:

Please refer to your user manual for correct battery designation depending on model year / type.

4-STROKE ENGINE MACHINES:

FUEL REQUIREMENTS

- Super Unleaded – minimum 97 octane.

SPARK PLUG DESIGNATIONS USED

NOTE: Because of electrical system changes over various model and model years please ensure you note your machines spark plug type and replace with a new, identical one. Options of plug designation to engine designation include:

- NGK CR8E – 250cc / 400cc / 450cc / 530cc / 660cc – Carburated Machines – Electrode gap: 0.7mm.

- NGK CR9 EIX – 250Fi EN Single Pipe / 300Fi EN Single Pipe /450Fi / 530Fi – Fuel Injected 4-Stroke Machines – Electrode gap: 0.7mm

- NGK R0045J-10 – 250Fi MX Single Pipe / 300Fi MX Single Pipe – Fuel Injected 4-Stroke Machines.

- NGK R0451B-8 – 250Fi MX/EN ‘Twin Pipe’ / 300Fi MX/EN ‘Twin Pipe’ / 450Fi MX/EN/SMK – Fuel Injected 4-Stroke Machines.

ENGINE OIL REQUIREMENTS:

- Running-in period = Original fill oil.

- Post running-in period = Oil type and volume as stated in your user manual.

ENGINE OIL QUANTITIES:

250cc / 400cc / 450cc / 450Fi / 530cc / 530Fi / 660cc –

- Oil change = 1.300 litres

- Oil and oil filter change = 1.350 litres

- Complete rebuild = 1.400 litres.

250cc / 300cc Fi models:

- Oil change = 1.200 litres.

- Oil and oil filter change = 1.250 litres

- Complete rebuild = 1.300 litres.

NOTE: For 660cc SMX Supermotard Competition machines please refer to your user manual as different crankcase options will alter the oil capacity levels.

IMPORTANT NOTES: Whilst completing oil changes on your TM Moto 4-Stroke machine you must ensure that the oil level in the inspection window is visible before and during engine running. Ideally the oil level should be showing as 3/4’s full in the inspection window at idle, upon increasing the engine rpm’s the oil level should lower slightly as the oil pump increases its flow rate around the engine, once the engine has settled back to idle the oil level should return back to 3/4’s full in the window, If not please add more oil until the desired measurement is achieved or slightly exceeded.

On 250Fi / 300Fi models, after long periods of rest, the majority of oil in the engine will eventually drain into the sump area and may give the impression of very low oil in the engine. Leaning the bike to the right for 10 seconds should then allow you to see oil appear in the sight glass window. If you are certain there is oil in the engine proceed to start the engine, the oil level should then stabilise once again in the sight glass window and give you an accurate oil level reading.

Do not be tempted to add more oil to the engine prior to running and checking the level, too much oil in the engine will lead to bad performance and running issues. Please ensure that the engine is not under or over-filled.

VALVE CLEARANCES:

- 250cc / 400cc / 450cc / 450Fi / 530cc / 530Fi / 660cc – Inlet 0.10mm > 0.15mm -/- Exhaust 0.15mm > 0.20mm

- 250 Fi / 300Fi – Inlet 0.10mm > 0.15mm mm -/- Exhaust 0.15mm > 0.20mm

CARBURETION:

Mikuni TDMR 36/39//41 – Keihin FCRD 39/41

As with the two stroke machines the carburetor settings should need little adjustment, the carburetors used on TM Moto 4-Stroke machines are very complex and should not be tampered with by inexperienced users, please refer to your TM Moto dealer for more information on these carburetors and for any technical help you may require with any running errors of the fueling system.

Remember always keep your carburetor clean and drain it after washing to ensure no moisture is trapped inside, this can lead to bad running and corrosion of the internal components.

ELECTRONIC FUEL INJECTION SYSTEMS:

Electronically Fuel injected machines require little in the way of maintenance and set-up, on TM Moto Efi equipped machines the fuel is filtered upon entering the fuel pump, to remove any impurities or particles in the fuel, the fuel is then pumped under high pressure through yet another finer filtration system to the main fuel line into the throttle body and then into the injector, the injector then atomizes the fuel into the oncoming air stream and enters the combustion chamber.

The metering and volume of fuel injected into the engine is controlled by the ECU which ‘pulses’ and times the delivery of the fuel supply, the ECU monitors throttle position, engine speed, cooling system temperature, air pressure, air speed and a number of other factors to calculate how much fuel is required at any given time, this metering system can adjust itself to one of its set parameters in milliseconds and is a far more economical approach to engine fueling, whilst not only regulating the fuel supply more economically further reductions in fuel usage are also gained from not having a ‘float chamber’ like a carburetor from which fuel can escape through the venting system.

The main advantage of Electronic Fuel Injection system, from a riders perspective, is that the electronic control of the fuel supply virtually eliminates hesitation (bogging) that is commonly found in carbureted machines and also the risk of engine stalling is lessened (although this is electronically monitored for safety) due to the electronics ability to alter the fueling characteristics of the engine and keep it running. A conventional ‘mechanical’ carburetor with a ‘float bowl’ will lose its fuel from its vent pipes and its fueling characteristics will change as it cannot utilise its carburetion jets unless they are bathed in fuel, this then leads to engine stall and increases the difficulty of re-starting the machine under high temperatures.

TM Racing’s policy of ensuring only the best components are used on their machines limits the use for changes to the Electronic Fuel Injection system, with components of exceptional quality, HGS exhaust systems for example, being fitted to the machine as a ‘standard’ part there is no need to ‘upgrade’ components like many other manufacturers machines and alter the working components of the engine, therefore altering the components that are factored in the metering devices of the ECU.

The ECU fitted to TM Moto machines is adaptable to a very small degree and will compensate for minuscule changes to the machines working characteristics without the need for program interfacing (re-mapping), this occurs by the ECU using the readings from the on-board sensors and correcting the fuel supply to a level which it calculates to be closer to the optimum setting. Whilst this type of system can overcome very small changes from the stock parameters it is not infinitely calculating or self intelligent, the parameters it can change to are determined by the TM Moto programming and the ECU is limited to those tiny adjustments only, huge changes in elevation and oxygen reduction for example will be too great for the system to overcome with the pre-installed parameters and re-mapping of the ECU will need to take place, however, in the real world these extreme examples are not likely to occur and the need to interface with the ECU is not necessary or recommended.If any problems occur with your TM Moto Efi equipped machine it should be taken to your TM Moto dealer for inspection and diagnostic test immediately. WARNING: TM Moto and TM UK do not advise alterations to the Electronic Fuel Injection system, its components or the pre-installed ECU parameters. This electronic device has been pre-programmed by TM Moto to give your TM Moto machine the maximum performance, reliability and safety. Failure to adhere to this warning could lead to engine component failure and/or injury

BATTERY REQUIREMENTS:

Please refer to your user manual for correct battery designation depending on model year / type