Start Your Engines!

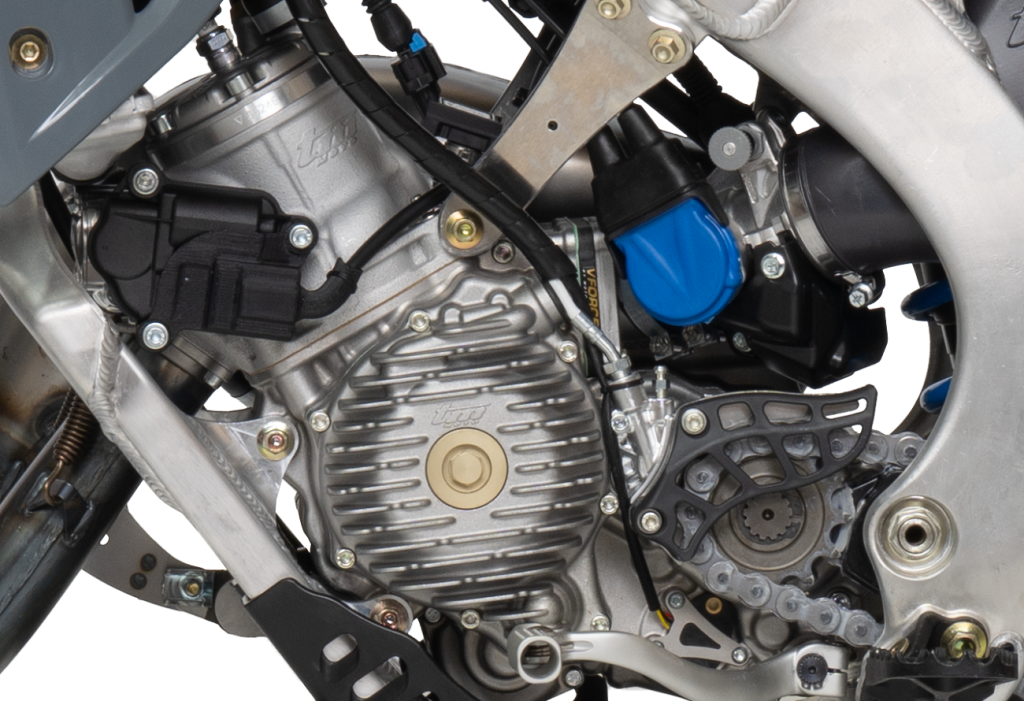

A simple guide to help you start your TM Moto 2-Stroke & 4-Stroke machines

Note: It is advised that machines fitted with electric start systems be started with the conventional kick-starter when cold, this reduces stress on the starter components and will allow the engine some run time to reach operating temperatures and complete it’s running-in cycle. A cold or ‘new’ engine will require some run time to reduce the ‘tightness’ of the engine allowing some ‘freedom’ of the components to be achieved and ensuring best performance and longest life. The electric-start system is not designed to withstand ‘in-gear’ starting where excessive clutch drag could cause premature wear or component failure – see bottom of page.

2-Stroke Engine Staring Procedures:-

After a visual safety check that the machine is ready to ride ensure that the fuel tank is filled with fresh super-unleaded fuel. Please adhere to the correct pre-mix ratio for your model using a high quality synthetic 2-Stroke racing premix oil on carbureted versions.

WARNING: you must ensure that the oil injection tank on Fi 2s / TSi (2-Stroke Fuel-Injection) versions is filled and the oil system is ‘primed’ as per the user manual – ‘2 Stroke Oil Circuit Filling’. Priming of the system must be completed after any and all maintenance work that would result in the system losing its ‘pressure’. The page from the user manual relating to the oil circuit filling system ‘priming’ procedure can be found at the bottom of this page. Failure to adhere to this warning could lead to engine damage. To prime the oil pump and perform simple diagnostic tests you will need the diagnostics port connection cable – Part No 68192. For ECU interfacing via a laptop computer device and the TM Moto software program (once installed) you will require the interface USB cable and diagnostic port connection cable kit – Part No’ F03876. You can also find a ‘how to’ on performing the oil priming procedure in the “Oils, Fuel & Electrical System” section.

- Turn the fuel tap to the ‘ON’ or ‘RESERVE’ position on carbureted machines

- For cold starts pull up/out the choke knob on the carburetor/throttle body, for a warm engine start the choke is not always necessary.

- Pull the kick-start lever to the ‘out ‘position and using the full travel of the lever kick downward until the engine fires.

- Replace the kick-start lever to the ‘in’ position.

- Once the engine is running allow the engine to warm by holding the throttle partially open at a steady and constant rpm (on cold starts the choke can be pushed to the ‘closed’ position after 20 seconds).

- Once temperature has begun to rise in the radiators and the engine cylinder begin to gently open the throttle allowing the revs to slowly increase, repeat this procedure several times allowing the rpm’s to increase gradually, this will allow the engine to ‘clean / clear itself out’ and remove any excess oil form the engine cases and combustion area. Once the engine has reduced smoking, the throttle response is sharp and there seems to be no hesitancy in the engine the bike is ready to ride. It is advisable to allow all of the engine components to come up to operating temperature by riding the bike gently for a short while. On new engines use no more than 1/2 throttle for the first hour of use.

4-Stroke Starting Procedure – Carbureted Engine Machines:-

After a visual safety check that the machine is ready to ride and the oil level is correct ensure that the fuel tank is filled with fresh Super-Unleaded fuel.

- Turn the fuel tap the ‘ON’ or ‘RESERVE’ position

- For cold starts pull out the choke knob and lock it into position, for warm engine starts the choke will not be necessary, under extreme high temperatures any reluctance of the engine to start will counteracted by using the ‘Hot-Start’ lever mounted on the handlebars, or on some models, located by the side of the carburetor on the right hand side of the machine (red coloured knob)

- Pull the kick-start lever to the out position and using a slow, smooth continuous stroke push the lever down until you hear an audible ‘click’ and stop allowing the kick-starter to return to its resting position at the top of its travel, the ‘click’ is the automatic decompressor re-setting itself and is a simple tell-tale that gives you an indication that the engine is now in the correct part of the engines ‘stroke’ cycle that will enable the easiest starting. The ‘click’, although inaudible under race conditions, is a marker that also gives the operator feedback through the leg, the resistance on the operators leg will change and this can be felt and interpreted by the operator who will learn to find the correct place by feel alone. With the kick-starter now at it’s resting position kick the starter lever downward from the top of its stroke right to the bottom in a continuous, rapid manner, do not attempt to kick using ‘half strokes’ like you may on a 2-Stroke engine machine, this kind of ‘kicking’ will only make starting more difficult as the complete engine cycle will not be completed. In the even that the engine does not fire it may be advisable to repeat the procedure but prior to kicking to start the engine give the throttle two short twists to allow the accelerator pump to introduce some fuel into the inlet tract to aid cold starting.

- Once the engine has fired and running steadily replace the kick-start ever to the ‘IN’ position.

- Once the engine is running steadily allow 30 seconds before closing the choke knob (if starting in extremely high temperatures release the ‘Hot-Start lever’ after several second allowing the machine to settle to idle), allow the engine to warm gently, there is no need to increase rpm’s or ‘blip’ the throttle on a 4-Stroke engine as there is nothing to ‘clean / clear out’. Once the radiators are warm you are ready to ride, do not allow the machine to sit idling for long periods, a 4-Stroke engine will increase it’s temperature much faster than a 2-Stroke machine leading to excessive heat build-up, boil-over and potential engine damage. It is advisable to allow all of the engine component to come up to operating temperature by using no more than 1/2 throttle for the first five minutes of use on the track

4-Stroke Engine Starting Procedure – Electronic Fuel Injection Engine Machines:-

After a visual safety check that the machine is ready to ride and the oil level is correct ensure the fuel tank is filled with fresh Super-Unleaded fuel.

Efi equipped machine do not have ‘fuel taps’ as the sealed system prevents fuel loss and leakages occurring.

- Pull the kick-start lever to the ‘out’ position, holding open the ‘cold’ / ‘hot’-start lever’ – which is located on the front brake master cylinder bracket / clutch master cylinder bracket / bottom of lighting control unit – or – on later some later models with ‘Twin’ Exhausts and/or the Keihin fuel injector type throttle body, a conventional type pull-out choke knob located on the throttle body itself. Making sure the throttle is closed kick the starter lever downward in a continuous, rapid manner, from the top of the starter levers travel right to the bottom.

WARNING: do not under any circumstances attempt to kick using ‘half/partial strokes’ like you may on a 2-Stroke engine machine or a carbureted 4-Stroke machine, this kind of kicking on a battery-less electronic fuel Injected machine will have the same effect as trying to start a carbureted 4-Stroke machine with the throttle wide open.

- With only 1 or 2 full travel kicks the engine should fire, if it does not then do not keep repeatedly trying to start the machine in this manner, the following actions must be applied simultaneously.

- 1. Hold the throttle open partially,

- 2. Depress the kill switch button (stop engine position)

- 3. Kick the starter lever from the top of its travel to the bottom 5 times

This procedure resets the system and discharges any excess fuel from the cylinder, now repeat the original starting procedure again.

- After the engine has fired replace the kick-start lever to the ‘in’ position.

- Once the engine has fired and is running keep the handlebar mounted ‘cold’ / ‘hot’ start lever’ or choke knob open for 60 seconds, this allows the Fuel Injection system time to re-calibrate itself and for the engine to warm initially (for engines starting in higher temperatures the ‘cold start lever’ / choke lever must still be used, effectively now becoming a ‘hot start lever’, but release the lever after only a few seconds of the engine firing), once the radiators are warm the bike is ready to ride. It is advisable to allow of the the engine components to come up to temperature by using no more than 1/2 throttle for the first 5 minutes of use on the track.

Note: Please do not leave engines ‘ticking-over’ unnecessarily, once the engine had been started and the ‘choke/hot start lever has been released you can gently begin to open the throttle slowly allowing the revs to rise in a smooth controlled manner – not in short sharp aggressive bursts as this could lead to ‘cough’ stalling of your performance racing machine. Performing start-up in this way will allow the engine to come up to temperature correctly, once both radiators have begun to warm sufficiently you can ride the machine, please allow a little track time at a reduced pace and engine revolutions to allow all the necessary engine components, the oil and the cooling system to reach their required operating temperatures.

NOTE: The Electric-Starting system fitted to your TM Racing / TM Moto machine is designed for starting the engine in it’s ‘unloaded’ state with the gearbox set in the ‘neutral’ position. It is not designed to withstand the continuously ‘variable’ clutch loadings of the engine trying to be started whilst ‘in gear’. Changes in engine temperatures that will affect the expansion rates of the clutch plates, alongside wear and possible degrading of clutch ‘control’ from over-use causing fluid performance loss from excess heat / poor maintenance that can affect operation, all contribute to increasing the friction (‘drag’) and therefore the stress on the electric-starter system, past its intended design limits. Using the starter in this way could cause excessive and premature wear or even failure of the components and it not advised nor ‘covered’ in any warranty.